All Categories

Featured

Table of Contents

- – Kitchen Exhaust Installation Alhambra, CA

- – Instant Air Solutions

- – Restaurant Hood Installation Alhambra, CA

- – Kitchen Exhaust Fan Motor Replacement Alhambra...

- – Kitchen Exhaust Fan Repair Service Alhambra, CA

- – Kitchen Hood Repair Service Alhambra, CA

- – Commercial Kitchen Hood Cleaning Alhambra, CA

- – Professional Hood And Duct Cleaning Alhambra...

- – Kitchen Exhaust Fan Motor Replacement Alhamb...

- – Hood Filter Replacement Alhambra, CA

- – Commercial Hood Cleaning Service Alhambra, CA

- – Kitchen Hood Maintenance Alhambra, CA

- – Commercial Hood Cleaning Service Alhambra, CA

- – Hood Vent Cleaning Services Alhambra, CA

- – Kitchen Hood Service Alhambra, CA

- – Instant Air Solutions

Kitchen Exhaust Installation Alhambra, CA

Ensure proper clearance over cooking surface areas for safety and efficiency. Determined in cubic feet per min (CFM), it needs to be appropriate for the volume of air created by your cooking equipment.

Ensure it matches the hood's specs and complies with neighborhood codes. Lots of business hoods featured integrated fire reductions systems for security. Make certain the system satisfies neighborhood fire codes and standards. Higher airflow can lead to increased sound; take into consideration quieter models or added soundproofing if noise is a problem. Search for hoods with removable filters and smooth surfaces for less complicated maintenance.

This sort of hood has a tendency to eliminate every type of grease air from your entire cooking area, and also brings fresh air back right into your industrial cooking area. The whole fresh air appears from the louvers in the front. This hood is actually Low-Profile which basically means its front is much shorter as contrasted to the back of the hood.

The ordinary cost of mounting a commercial hood varies from $964 to $1,174 per square foot. Most of the industrial hoods measure around 10 to 14 feet long which makes the whole setup cost $9640 on the lower side and $16,436 on the greater side depending on the size of your kitchen.

Restaurant Hood Installation Alhambra, CA

These hoods are typically mounted over dishwashing machines, steamers, or various other tools that generates a whole lot of condensation. They aid protect against excess moisture in the kitchen area, which can result in mold and mildew, mold, or damages to wall surfaces and ceilings. Fitting an industrial extractor hood involves a number of key steps: Determine the most effective area based upon the type of food preparation equipment and airflow requirements.

Attach the ductwork to air vent air outside, making sure proper sizing and fire safety and security compliance. Attach the exhaust fan (inline or roof) to preserve regular air flow. Integrate electrical wiring and, if required, a fire suppression system. Test air movement (CFM), verify code conformity, and look for leaks or noise issues. Specialist setup is strongly advised due to the complexity and safety and security laws included.

This style enhances effectiveness by catching smoke, heavy steam, oil, and heat before they disperse into the area. These hoods are frequently utilized in smaller kitchen areas or where space is limited and are much more energy-efficient contrasted to traditional above hoods.

Business restaurant air flow systems existing numerous challenges to modern cooking areas. For that reason, they must be installed properly from the start. Cooking area oil hoods, condensation hoods, and exhaust followers must adhere to state and local building codes. Plus, they need to function within the building's format to keep air flowing efficiently.

Kitchen Exhaust Fan Motor Replacement Alhambra, CA

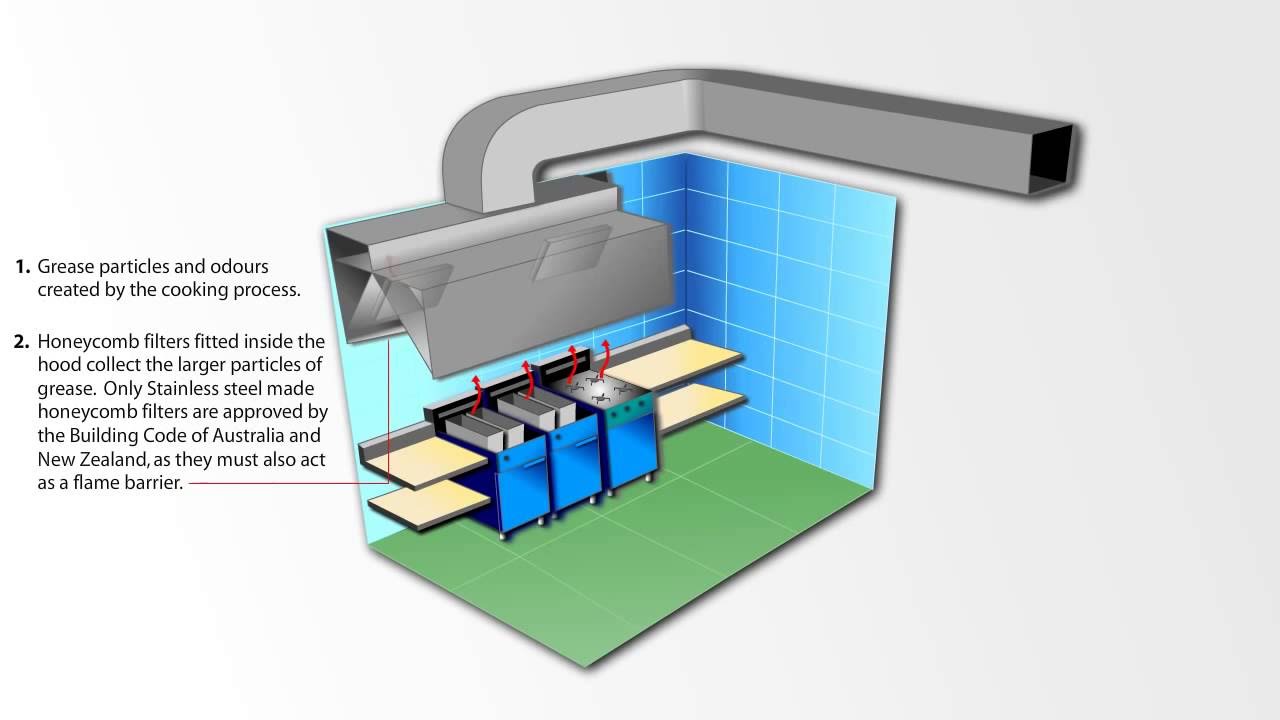

A business kitchen exhaust system is crafted to remove warm, smoke, vapors, and grease-laden air from cooking areas. These systems enhances air top quality by changing stale air with fresh air, avoids the buildup of grease, which can position fire dangers and preserves a comfy functioning environment for team. Below is the major components of an industrial cooking area exhaust system:1.

Set up ducting, reducing bends, and guaranteeing correct insulation to decrease condensation. Placement fans at the end of to facilitate efficient air expulsion. Install these devices purposefully to stabilize air stress and ensure a sufficient supply of fresh air. Routine upkeep is vital for safety and security and efficiency. Set up regular examinations to inspect for: Oil build-up in hoods and air ducts.

Creating and installing a business kitchen area exhaust system is a complex yet vital job that requires cautious planning and adherence to regional regulations. By comprehending the elements, design elements, and installment processes, restaurant owners and kitchen area supervisors can make sure effective ventilation, boosting both security and comfort in their culinary atmospheres.

A: There are a number of factors that relate to hood style. You decide what you are going to be cooking, which will certainly dictate your equipment, which in turn will determine what kind of hood you will need. There are likewise a number of code issues that will certainly choose the details hood that will match your needs.

Kitchen Exhaust Fan Repair Service Alhambra, CA

Our hoods are ETL checked, noted and classified to UL 710 standards. Those examinations are mostly performance based and will pass inspection and get authorization, however an improper installation can make any kitchen hood fall short.

You can't. However, jab a hole in the side and voil, you can take a breath. In this scenario you are the exhaust follower and the hole is the makeup air. Your exhaust merely will not collaborate with out the hole in the side of the bottle, take a look at our makeup air systems.

Kitchen Hood Repair Service Alhambra, CA

This is a code problem. The International Mechanical Code states that when MUA has the capacity to reduce the comfort of the area, it must be warmed.

A: That depends upon the kind of hood being used or your area (some states or cities call for every little thing to be warmed). Interior compensating hoods direct the MUA internally to make sure that the air never gets in the room, for that reason the MUA in this instance has no capability to lower the comfort of the space.

Most of the moment, brand-new construction does not need tempered MUA. If the hood system and the heating and cooling system are created to enhance one an additional beforehand, a pricey heated system can be avoided New construction must does not need to be geared up with heated MUA, since when the developers are conscious of the negative pressure brought on by the hood beforehand, the a/c system can be sized to make up for any kind of lacking air.

Commercial Kitchen Hood Cleaning Alhambra, CA

A: Yes we can offer fire suppression, however we have located that having a hood system pre-piped does not save cash and will cause undue headaches in the future. If a system is pre-piped, a licensed installer will certainly still need to be contracted to do the last hookup and to do the needed screening for the local authorities.

A: It is of the utmost significance to have a certified specialist with experience in hanging industrial kitchen area hood systems. KSH is always available to sustain your setup process all the way with to the end, a seasoned specialist will certainly save time and hassle. A: A permit is required for hood approval and installment.

Trying to circumvent getting a license can trigger significant issues, since eventually someone will discover that you don't have one. Whether its the fire marshall or the health and wellness division, the structure department will get involved eventually and will certainly ask where the hood authorization is. A: First, learn who will certainly be providing the permit.

Professional Hood And Duct Cleaning Alhambra, CA

If you are not sure, simply contact any one of the three (beginning in your area prior to calling the state) and provide them the project address and they will certainly inform you if you remain in their territory. As soon as you have established that you are speaking with the right division, merely ask what the procedure is.

They will ask you for a trine or four stamped drawings with a permit application. There might be other steps and we always recommend pleasantly asking what else is required to save time in the future. A: IMC 507.2.1.1 states that when cooking takes place the exhaust system is to immediately turn on.

When that takes place, heat swiftly accumulates in the cover melting the links in the fire reductions consequently detonating the fire suppression itself. To say the least, this has provided fairly an issue as a result of the reality that a lot of cooking home appliances are fueled with gas and electric interlocking is challenging and very expensive.

Kitchen Exhaust Fan Motor Replacement Alhambra, CA

If the hoods are not turned on, the warmth will certainly develop, today the probe detects the rise in temperature and immediately activates the fans. A: A standoff is utilized to gain clearances from flammable walls or ceilings. It is extremely suggested that you talk to your regional structure authority to figure out if this serves or not.

Considering that hood setups are really costly, it makes excellent financial sense to validate and reveal all information prior to proceeding. The structure division A: The size of the exhaust fan and makeup air systems are determined by the devices under the hood and the size of the hood. KSH uses a wide range of exhaust and supply fans yet they need to be defined separately.

Things like air duct runs, shifts and fixed pressure all can affect what a fan will certainly press or pull. Restaurant Kitchen Ventilation Alhambra. A: Increasingly more, developing divisions are enforcing IMC 306.5.1. When tools is mounted on roof coverings with a pitch of 3:12 or greater, and 30" or even more off quality, after that a service system will certainly be required

Hood Filter Replacement Alhambra, CA

These vent hood exhaust followers are roof-mounted with an inlet and electrical outlet that are positioned 90-degrees from one another. These fans lie in the interior duct and are used where external fan installing verifies to be a not practical option. Your vent hood setup crew will certainly let you recognize which type of fan is ideal for your business kitchen design.

This fan can be different or it can be a part of your overall heating and cooling system. There are 2 kinds of ventilation hoods. This is one of the most common sort of air vent hood. It is placed on one side over a home appliance like a stove or deep fryer. This vent hood is best made use of in an open floor plan commercial cooking area format.

Commercial Hood Cleaning Service Alhambra, CA

If this doesn't happen, there might be an obstruction or other issue. If your commercial cooking area ends up being full of dry and revolting smoke, the staff might become hurt, and your food can become negatively affected. This is a sure indicator that your vent hoods need to be repaired or changed.

Call a air vent hood repair experts quickly to get your kitchen area air supply back to breathable high quality. If your heating and cooling unit appears to be not working, your vent hood could be to blame. Several of that grease and soot can discover its way right into your ducts and a/c elements, mucking them up and making them work more challenging than they need to.

Kitchen Hood Maintenance Alhambra, CA

Business kitchen areas in resorts, dining establishments and various other hospitality sectors are always busy. Workers in these kitchens usually spend additional changes. Lengthy working hours can cause an accumulation of smoke and warm. Due to the fact that of this buildup, a lot of dining establishment kitchens set up a kitchen area hood. Alturas service providers help you do just that, with a group of hood installers in Los Angeles.

Here are a few of the factors to take into consideration before you call a handyman for hood installation. If you are a brand-new dining establishment proprietor, and trying to find business hood installation firms near you in Los Angeles, this list will help you locate the ideal one. See to it to hire certified service technicians that recognize restaurant air flow systems.

Hire a person who already has experience with the leading commercial hood brands that you are taking into consideration. Safety is one of the crucial aspects to consider for Cooking area ventilation.

These air vent hood exhaust followers are roof-mounted with an inlet and outlet that are put 90-degrees from each other. These fans are situated in the interior air duct and are used where outside fan placing proves to be an unwise service. Your vent hood installment crew will let you recognize which type of follower is suitable for your commercial cooking area design.

Commercial Hood Cleaning Service Alhambra, CA

This fan can be different or it can be a part of your general cooling and heating system. There are two types of air flow hoods. This is one of the most common type of air vent hood. It is placed on one side over a device like an oven or deep fryer. This vent hood is best utilized in an open floor plan business kitchen area format.

If this doesn't occur, there can be an obstruction or various other issue. If your commercial cooking area comes to be full of dry and disgusting smoke, the team can become damaged, and your food can become negatively influenced. This is a sure indicator that your air vent hoods need to be fixed or replaced.

If your A/c system seems to be on the fritz, your vent hood could be to criticize. Some of that oil and soot can locate its way into your ducts and Heating and cooling components, mucking them up and making them function more challenging than they require to.

Hood Vent Cleaning Services Alhambra, CA

Due to the fact that of this buildup, a lot of dining establishment kitchens mount a kitchen hood. Alturas contractors help you do simply that, with a group of hood installers in Los Angeles.

Below are some of the factors to consider prior to you contact a handyman for hood installment. If you are a new dining establishment owner, and seeking business hood setup companies near you in Los Angeles, this checklist will certainly aid you locate the right one. Make certain to hire certified technicians that understand restaurant air flow systems.

Kitchen Hood Service Alhambra, CA

Instant Air Solutions

Address: 412 W Dryden St Apt 6 Glendale, CA 91202Phone: (747) 307-6363

Email: [email protected]

Instant Air Solutions

Hire somebody who already has experience with the top business hood brand names that you are thinking about. Security is one of the important elements to consider for Kitchen area ventilation.

Fire Suppression System Inspection Alhambra, CAKitchen Hood Maintenance Alhambra, CA

Commercial Hood Installation Alhambra, CA

Commercial Kitchen Ventilation Alhambra, CA

Restaurant Hood Cleaning Service Alhambra, CA

Close By Seo Specialist Alhambra, CA

Near You Seo Agencies Alhambra, CA

Instant Air Solutions

Table of Contents

- – Kitchen Exhaust Installation Alhambra, CA

- – Instant Air Solutions

- – Restaurant Hood Installation Alhambra, CA

- – Kitchen Exhaust Fan Motor Replacement Alhambra...

- – Kitchen Exhaust Fan Repair Service Alhambra, CA

- – Kitchen Hood Repair Service Alhambra, CA

- – Commercial Kitchen Hood Cleaning Alhambra, CA

- – Professional Hood And Duct Cleaning Alhambra...

- – Kitchen Exhaust Fan Motor Replacement Alhamb...

- – Hood Filter Replacement Alhambra, CA

- – Commercial Hood Cleaning Service Alhambra, CA

- – Kitchen Hood Maintenance Alhambra, CA

- – Commercial Hood Cleaning Service Alhambra, CA

- – Hood Vent Cleaning Services Alhambra, CA

- – Kitchen Hood Service Alhambra, CA

- – Instant Air Solutions

Latest Posts

Carmel Valley Bradford White Water Heater Repair

Family Portraits Photography Pomona

Wedding Elopement Photographer Irvine

More

Latest Posts

Carmel Valley Bradford White Water Heater Repair

Family Portraits Photography Pomona

Wedding Elopement Photographer Irvine